|

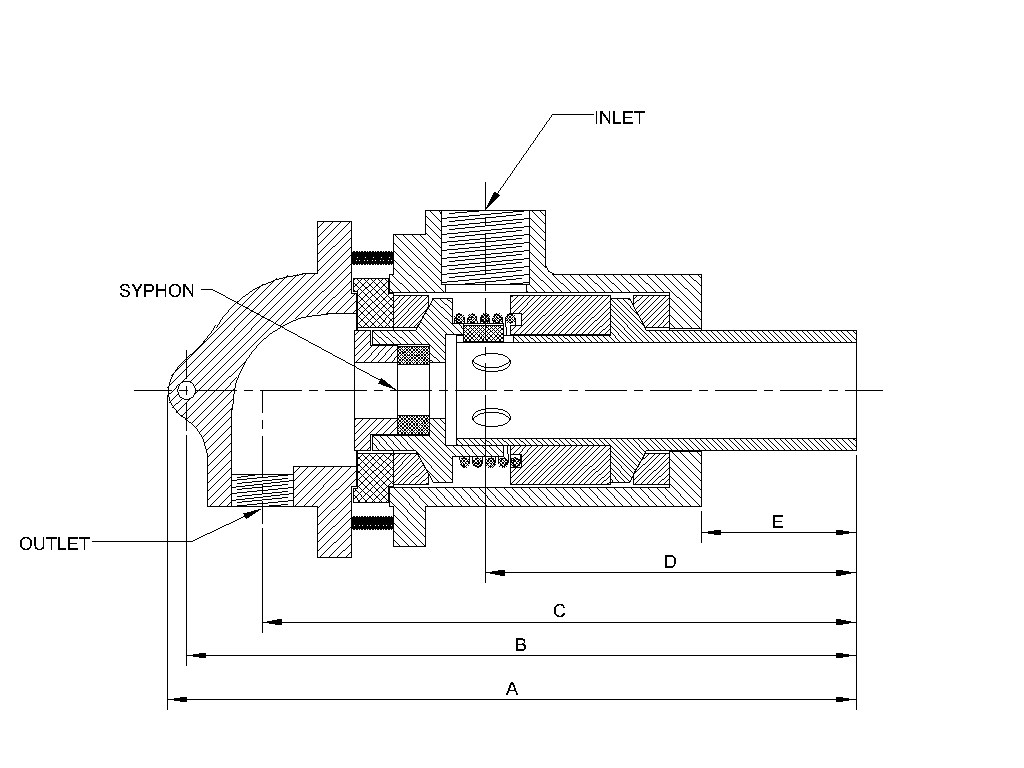

SIZE |

INLET |

OUTLET |

SYPHON |

A |

B |

C |

D |

E |

|

2 1/2" |

2" |

1 1/2" |

1" |

427 |

422 |

361 |

241 |

91 |

|

3" |

2 1/2" |

1 1/2" |

1" or 1 1/4" |

456 |

441 |

395 |

250 |

104 |

|

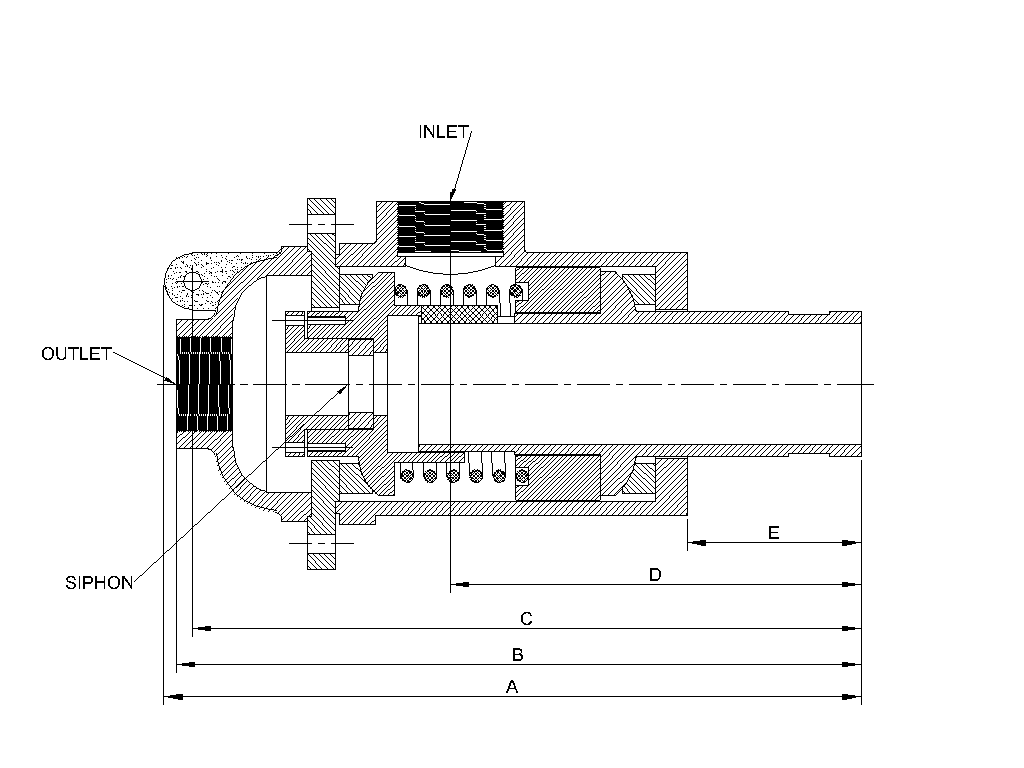

SIZE |

INLET |

OUTLET |

SYPHON |

A |

B |

C |

D |

E |

|

3 1/2" |

2" |

2" |

1 1/2" |

508 |

526 |

490.5 |

297 |

137 |

|

4" |

3" |

2 1/2" |

2" |

545 |

535 |

522.5 |

321 |

136 |

|

5" |

4" |

3" |

2 1/2" |

645 |

641 |

511.5 |

373 |

158 |

| TECHNICAL SPECIFICATION | |

|---|---|

| SIZE | 3/4″ to 5″ |

| PRESSURE | 0.5 to 12 barg |

| TEMPERATURE | 100º to 300º C |

| SPEED | Up to 200 MPM (50 RPM) |

| MEDIA | Steam |

| TECHNICAL SPECIFICATION | |

|---|---|

| SIZE | 31/2″ to 5″ |

| PRESSURE | 0.5 to 12 barg |

| TEMPERATURE | 100º to 300º C |

| SPEED | Up to 200 MPM (50 RPM) |

| MEDIA | Steam |

Sn Type Rotary Joint Is Intended Mostly For Machines With Low Speeds.

Allignment is not necessary when we want to install the rotary joint. As there is a guide to support the rotary joint, the friction and wear are slightly higher compared with another rotating type of rotary joint. But that we can eliminate if we change the material of construction of the seals.